|

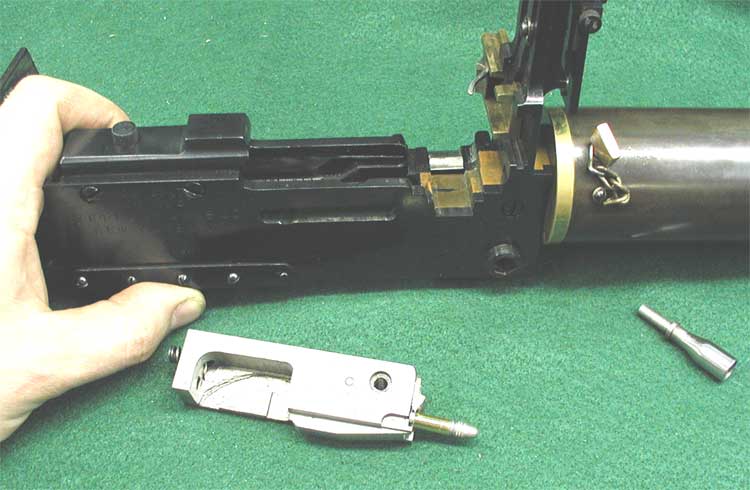

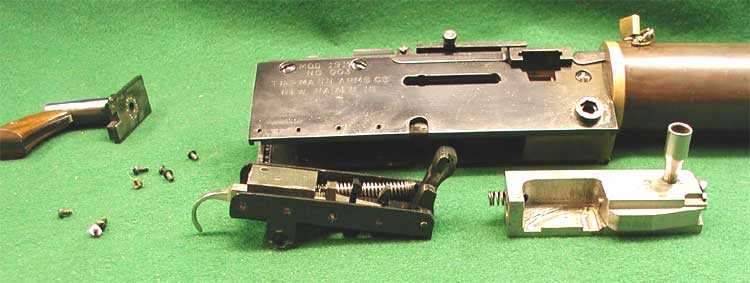

Now that the outside of this

gun has been explored, lets take a look into its internal design.

The first thing that had to be done was to find

out how it

could come apart. It disassembles totally different

than the later production guns. The buffer tube is actually the key to the

disassembly. When the buffer screw is turned out we find it works as a recoil

spring retaining device. Without the recoil spring and guide removed the back

plate with pistol grip can not be slid upward.

When the recoil spring and

guide rod are removed the pistol grip assembly can be slid upward and out of

the back of the receiver. The bolt can be moved backward so the cocking handle

lines up with the removal pocket in the cocking slot. With the handle removed,

the bolt can be removed all the way out. Notice the massive cutout in the rear

end of the bolt assembly. This is for the hammer rotation of the trigger pack.

There is a small "buffer" spring in the back of the bolt to reduce

recoil. This spring was removed in the later guns because of the extended length

of the bolt cycle stroke per shot and recoil reduction was not a concern

anymore.

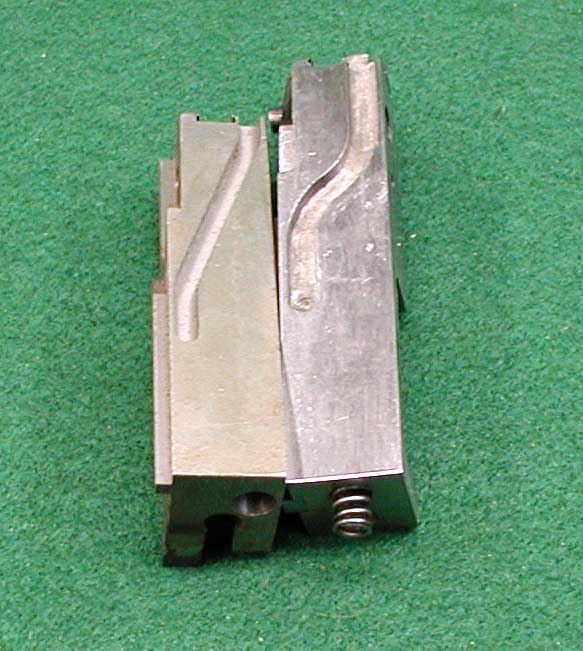

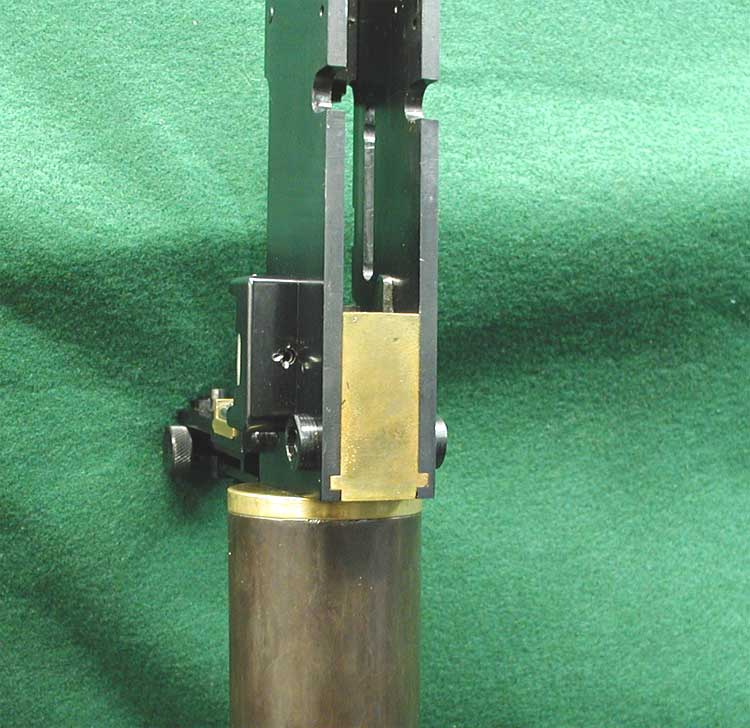

This

picture above shows the first thoughts of the left side plate cam design. It

simply is a small milled path that drives the extractor downward on the rear

stroke of the bolt. The production guns have a forward extractor manipulation

design as well as a spring loaded "flipper" that made a positive cam

track path for each bolt cycle. Also seen here is a small leaf spring in the

cam track that allows extractor pressure on the round in the feed tray, this

is till used in the production models.

This

picture shows the cam slot in the top of the bolts as well as the bolt length

differences. The cam transition on the bolt on the left is the current design

which makes the top slide react in a smooth fashion when the bolt cycles. The

right (prototype) cam groove has a violent reaction to the top slide when its

bolt cycles during firing. Notice the buffer spring in the prototype bolt.

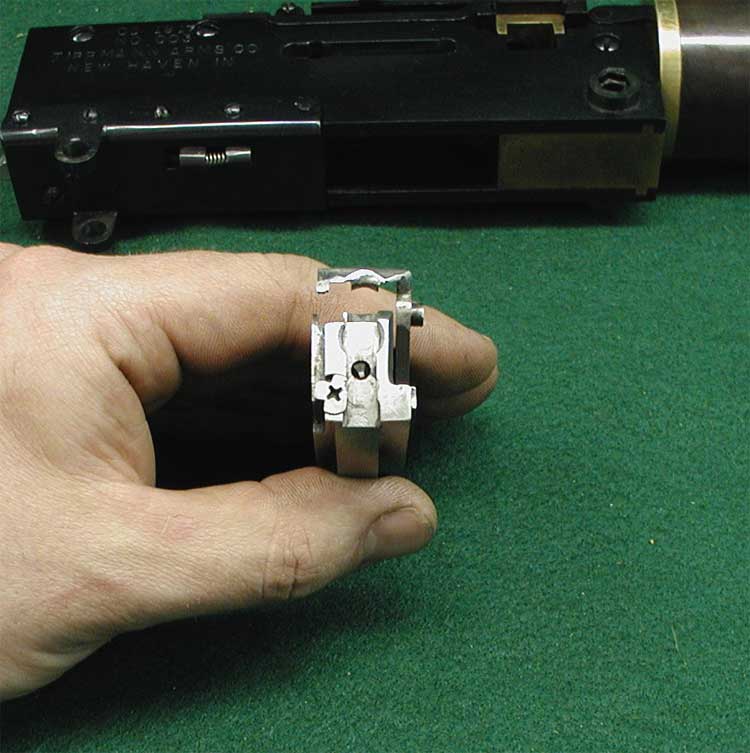

Above

is the heart and soul of the guns mechanism, the extractor. One of the

problems with a Browning belt-fed design is the fact that the cartridge needs

to be held in position when it is being chambered. This extractor design did

three things. This small delicate part needed to extract a round from the belt

that was sitting in the feed tray and keep it captivated in the T-slot of the

bolt face. It then had to slide the round down the bolt T-slot by means of the

drive lug riding in the cam track milled into the left side plate. The rim of

the 22 cartridge was captivated in the T-slot by a "switch" that was

activated by the far outside of the extractor. The little extractor ear would

push down on the "screw" type switch temporarily closing the T-slot.

As the nose of the cartridge was entering the chamber the "switch"

was released by a small lug that pushed the "switch" upward again

thus resetting it for the next round to travel thru. This lug will be shown in

a picture further down. The picture below shows how a cartridge could be

captured inside of the T-slot by the extractors manipulation. This entire

process was timed so finely and was no doubt very time consuming to

manufacture.

The

picture above is a close up of the "lug" mentioned in the extractor

operation above. This lug is in the right side plate and sticks out the rear

of the breech block. It engages the "switch" in the face of the bolt

to release the empty cartridge so it can fall out the T-slot.

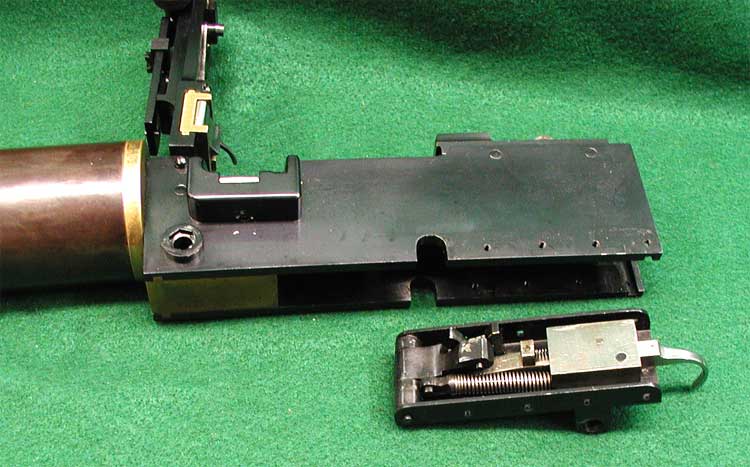

Here

is the trigger/hammer pack disassembled from the bottom of the gun. The hammer

is shown in the "cocked" position. This model had NO provision for a

safety what so ever.

The

above picture is of the trigger/hammer pack taken out of the gun and it is in

the fired position. Well,

I hope you have enjoyed this little tour of the past. It was a true pleasure

to see the insides of this gun and to see what the first ideas were that led

to its production. If any of you might have a similar model like this with

unique features, Please let us know, we would like to include it in this

archive page. return to gallery

|